Durante el debate sobre la reducción de gases carbónicos de efecto invernadero se han propuesto diversas teorías y tecnologías que pueden llegar a reducir el impacto de los combustibles fósiles.

Un ejemplo de esto es la propuesta de secuestrar los gases de combustión de estaciones termoeléctricas. Se ha propuesto que el CO2 que normalmente es emitido a la atmósfera sea inyectado en los mantos subterráneos del fondo de los océanos.

En el periodo de transición que probablemente veremos entre las energías del futuro (renovables, fusión, etc) y las tecnologías con las que contamos actualmente, quizás podemos proponer soluciones que nos permitan eficientar y optimizar las tecnologías con las que contamos actualmente.

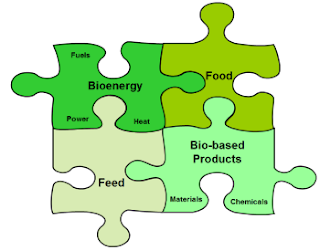

Una de estas soluciones es utilizar biorreactores de algas que pueden depurar una parte importante del CO2 de las plantas termoeléctricas para producir los aceites que son la materia prima para fabricar biocombustibles como el biodiesel.

Estos biocombustibles generalmente no contribuyen significativamente a añadir más carbono al ciclo de carbono si su producción está bien gestionada.[1]

Biorreactores con configuraciones similares han sido utilizados satisfactoriamente de forma comercial para la producción de lípidos de algas que se usan en la industria de los alimentos.

[1] Ejemplos para no seguir: El bioetanol que se produce en EE.UU. a base de maíz con un balance energético muy pobre y la deforestación en Indonesia durante la producción de aceite de palma para la producción de biodiesel